Show me and I may remember,

Involve me and I’ll understand.”

This ancient Chinese proverb is as relevant today as it was

during the height of the Ming dynasty over six hundred years ago. People learn

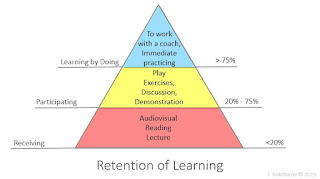

in a variety of different manner but the retention rate of the material

presented increases dramatically when you have to get up from behind the desk

or conference table and actually get your hands on the process. After all, this

is where the theoretical meets the practical.

The concept of experiential learning or learn-by-doing is

not new. Around 350 BC, Aristotle wrote in the “Nichomachean

Ethics "for the things we have to learn before we can do them, we

learn by doing them". Unfortunately for a concept that has been around for

centuries, in my experience, I find most organizations ignoring this practical

approach and settling on the classroom PowerPoint presentation scenario. 5 days

and 1200 slides later, the students emerge from the darkened class room bleary

eyed, bored to tears and no better prepared today than they were a week ago to

attack and fix real problems. Sure they might have retained a couple knowledge

tid-bits, if they weren’t texting under the table, but was the modest value-added

gain worth 5 days?

Now compare that approach to a Boot

Camp. Solving real world problems using the necessary and appropriate Lean

& Six Sigma tools for your particular business case. Learn how to engage

and involve everyone, not just a select few.

Define the scope, gain agreement, measure current state, determine and

fix root cause, & implement sustainability measures. The trick is making

this typically complicated process simple and fast. This process results in hundreds

of improvements a year rather then 1 a quarter

If

your interested in a high intensity, action filled day with several on-site

follow ups tackling the issues that keep you up at night, join us on June 7th. (Click image above for registration details)

Otherwise don’t be surprised with the normal less than 20% learning retention

and the lack of speed and unresolved business issues that result.